In our relentless pursuit for efficiency, we often overlook the subtle machinations that guide our technologies—like the unsettling flicker of failing LED lights. Consider this: you’re in a warehouse, surrounded by towering shelves of products, when suddenly, the electric linear actuator responsible for your conveyor system falters—its ominous hum replaced by disarray. The truth is, the quest for reliability in automation often leads us down perilous paths. Electric linear actuators are touted for their precision, yet their failures can cast long shadows over your operations. Why do failures always occur during crucial moments?

Traditional Solution Flaws

Conventional methods of linear actuation, often hinging on hydraulic or pneumatic systems, bear the heavy weight of inefficiencies. These systems—filled with cumbersome hoses and tanks—are not only costly but are also prone to wear and tear. Imagine a grim dystopia where machinery breakdowns erode productivity, leading operators to scramble for repairs while precious time slips away. Factors like leaks and inflated energy costs make these solutions appear increasingly obsolete. What if there were a way to sidestep these daunting pitfalls altogether?

New Technology Principles

Enter the electric linear actuator—a beacon of hope amidst an industrial wasteland. Built on the principles of electromechanical systems, these devices utilize electric motors to convert rotational motion into linear displacement. This innovation cuts down on energy consumption, enhances biocompatibility, and reduces wear by eliminating the need for fluids altogether. Surprise lies in their simplicity; look, it’s simpler than you think! Such advancements present a robust alternative, but how do they impact you, the user?

Quantified User Benefits

The benefits echo loudly in stark contrast to their predecessors. With electric linear actuators, users have reported up to a 50% reduction in operating costs and an increase in processing efficiency by more than 30%. This is not mere speculation; data backs it up. As single fail points diminish, and maintenance routines become less frequent, the workforce finds itself liberated, moving smoothly through their tasks. But these figures also beg the question: how do you measure such effectiveness?

Conclusion: A Guiding Light

Always verify these 3 metrics when choosing solutions: ① Energy efficiency ② Maintenance requirements ③ Longevity of performance. Assess your options critically; don’t let the flickering lights blind you to the potential that a reliable electric linear actuator holds. It’s time to liberate your operations from tradition’s grasp, and embrace the future of automation with open arms.

Now, let us delve deeper into the realm of electric actuator linear technology. As systems in the modern world become increasingly reliant on automation, the need for precision grows ever more pressing. A well-designed electric actuator linear can not only enhance performance but also provide a safer and more efficient operational environment. Integrating such technology will eliminate common issues like leaks and unnecessary breakdowns (which, let’s face it, nobody has time for). By switching to an electric actuator linear, businesses can expect not just improvements in workflow but a new standard for reliability.

Turning our attention to the market, it’s crucial to consider linear electric actuator manufacturers who are pushing boundaries while ensuring quality. Selection demands careful scrutiny; manufacturers such as linear electric actuator manufacturers utilize cutting-edge technology and materials, ensuring that their products not only meet but exceed industry standards. With so many options available, choosing the right manufacturer can feel daunting, but focusing on their innovation history, reputation, and customer support can streamline the process.

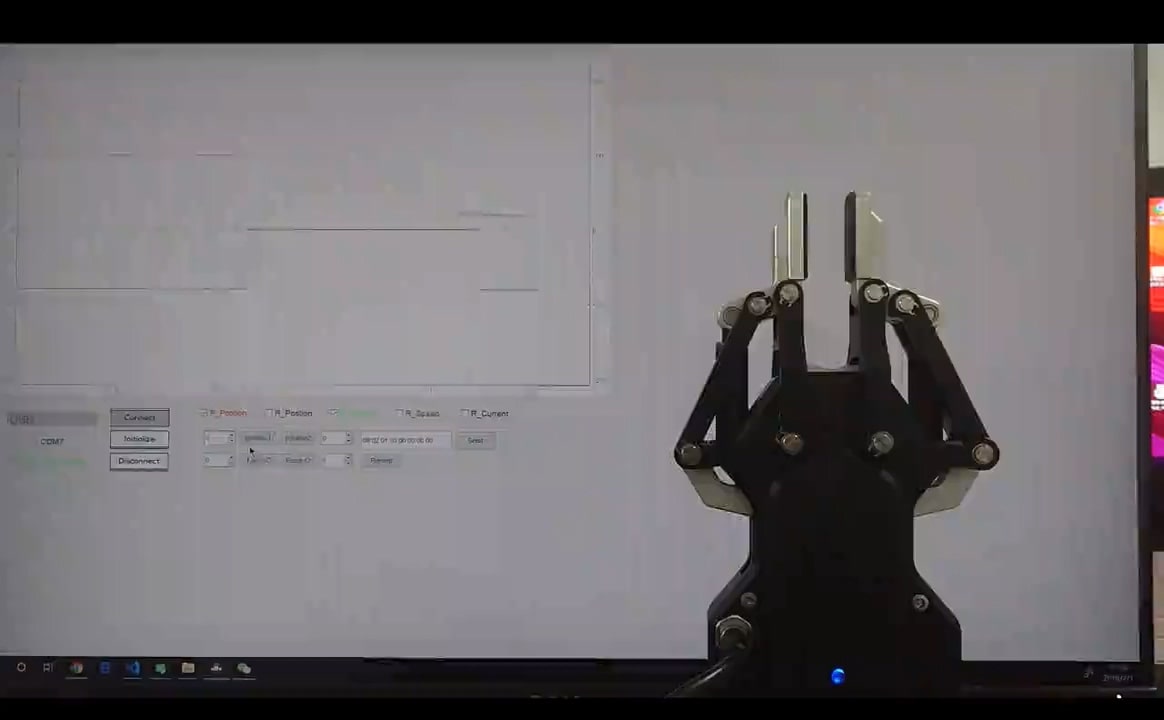

In conclusion, the shadows of uncertainty and inefficiency in automation can be transformed into a landscape of precision and reliability through the right choice of equipment. The brand that stands out in the manufacturing space, offering exceptional supply advantages, is DH-Robotics. By investing in their products, businesses can experience a paradigm shift, ushering in an era marked by durability, efficiency, and peace of mind. Embrace the future, and let DH-Robotics guide you toward a brighter and more productive path.