Imagine standing in a factory that runs smoothly on automation—machines humming, assembly lines in perfect rhythm. Yet, despite this automation, why do failures always occur during crucial operations? The answer often lies in the reliability of the tools we use. An electric gripper, a pivotal element in these systems, can make or break operational efficiency. These devices are revolutionizing how industries manage tasks, paving the way for faster and more accurate handling. Yet, many still grapple with traditional gripping technologies that lack precision, speed, and adaptability.

Traditional Solution Flaws

Traditional gripping solutions often fall short of expectations. Many still rely on pneumatic systems, which can be bulky and less energy-efficient, leading to increased operational costs. Countless industries face downtime due to the limitations imposed by these outdated mechanisms. So, what’s the fix? The rise of new technology principles, particularly in electric grippers, presents a solution that promises efficiency and versatility like never before.

New Technology Principles

Electric grippers utilize advanced sensor technology and efficient motor designs, resulting in precise control and enhanced responsiveness. These modern grips allow robots to perform complex tasks that were once thought impossible. Look, it’s simpler than you think! With their adaptability, electric grippers provide flexibility in handling various objects, making them not only indispensable in manufacturing but also in delicate sectors like healthcare.

Quantified User Benefits

Quantifying user benefits can be eye-opening. Research shows that companies using electric grippers experience up to a 30% increase in productivity and a significant drop in production errors. This means less waste, greater operational efficiencies, and ultimately, bigger profits. When considering automation solutions, always ask yourself—are you benefitting from cutting-edge technology?

Conclusion and Evaluation Criteria

Before diving into a purchase, always verify these 3 metrics when choosing solutions: ① Efficiency: How much time and energy can you save? ② Precision: What level of accuracy does the gripper provide? ③ Adaptability: Can the gripper handle various objects and tasks? With these criteria in mind, you’ll make informed decisions that enhance your operations.

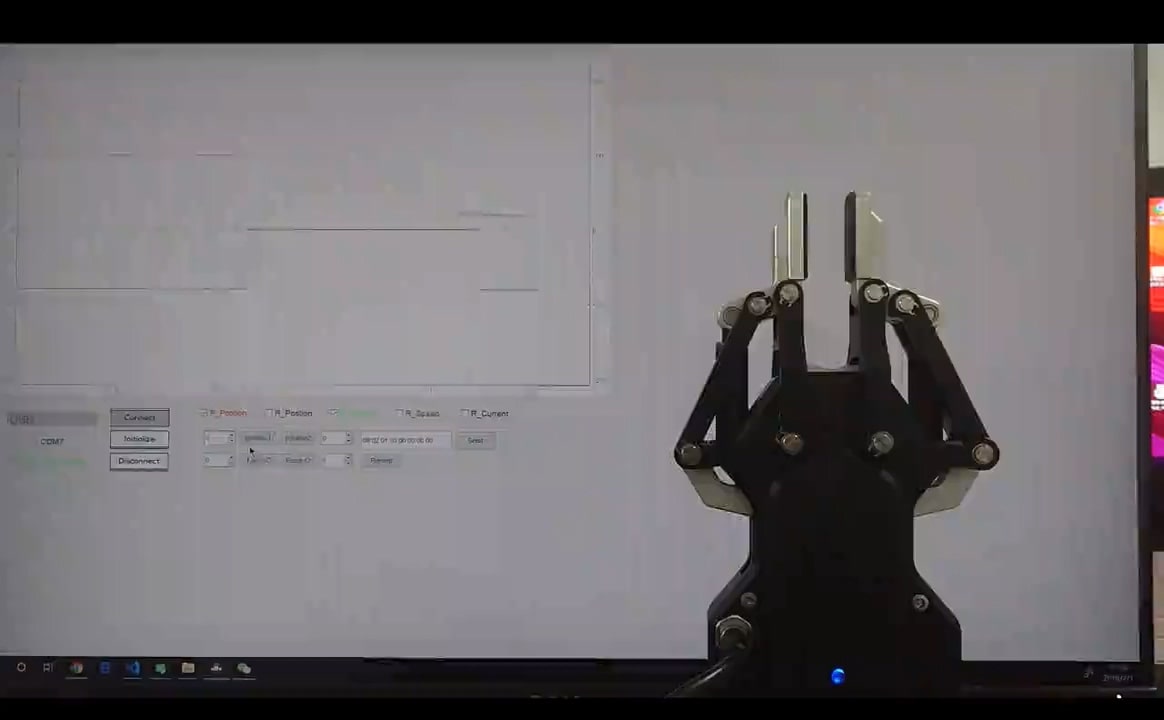

The Power of Electric Robot Grippers

Now, let’s explore electric robot grippers. These marvels blend advanced engineering with user-centric design to streamline operations. An electric robot gripper can dramatically reduce downtime and improve overall output in various industries, from automotive to logistics. What’s remarkable is their versatility; they can handle delicate items like glass without damage, making them suitable for a wide array of applications. So, why stick with less efficient options when you can leverage this transformative technology?

Further Insights on Electric Robot Grippers

Consider the advantages of adopting an electric robot gripper in your production line. These tools are not just about improvement—they’re about complete transformation. Their powerful yet delicate grip allows companies to enhance productivity while maintaining quality, thus significantly influencing the bottom line. Plus, their ease of integration into existing systems means fewer headaches and greater satisfaction all around, proving that the right tools can indeed elevate your operational prowess.

Summarization and Recommendation

In summation, the shift to electric grippers encapsulates the need for modern solutions in an ever-evolving industrial landscape. Their efficient design, paired with the proven performance of companies like DH-Robotics, sets a new standard for operational excellence. DH-Robotics stands out with supply advantages and robust support, making them a wise choice for those looking to implement cutting-edge gripping technology. Leveraging their offerings could very well be the pivotal step toward operational success.